Repair Services for Grain Auger Conveyor Gearbox

Introduction to Repair Services for Grain Auger Conveyor Gearbox

Repair services for grain auger conveyor gearbox offer essential maintenance and repair solutions for agricultural machinery. These gearboxes play a crucial role in moving grain efficiently and reliably, and ensuring they are properly maintained is essential for optimal performance.

Advantages of Repair Services for Grain Auger Conveyor Gearbox

- Preventative Maintenance: Regular servicing and repairs can help prevent costly breakdowns and extend the lifespan of the gearbox.

- Improved Efficiency: Well-maintained gearboxes operate more efficiently, reducing energy consumption and increasing productivity.

- Enhanced Safety: Properly functioning gearboxes reduce the risk of accidents and injuries in the workplace.

- Cost Savings: Timely repairs can prevent major damage and the need for expensive replacements.

- Expertise: Professional repair services have the knowledge and tools to diagnose and fix gearbox issues effectively.

- Customized Solutions: Repair services can provide tailored solutions based on the specific needs of the gearbox and machinery.

Applications of Repair Services for Grain Auger Conveyor Gearbox

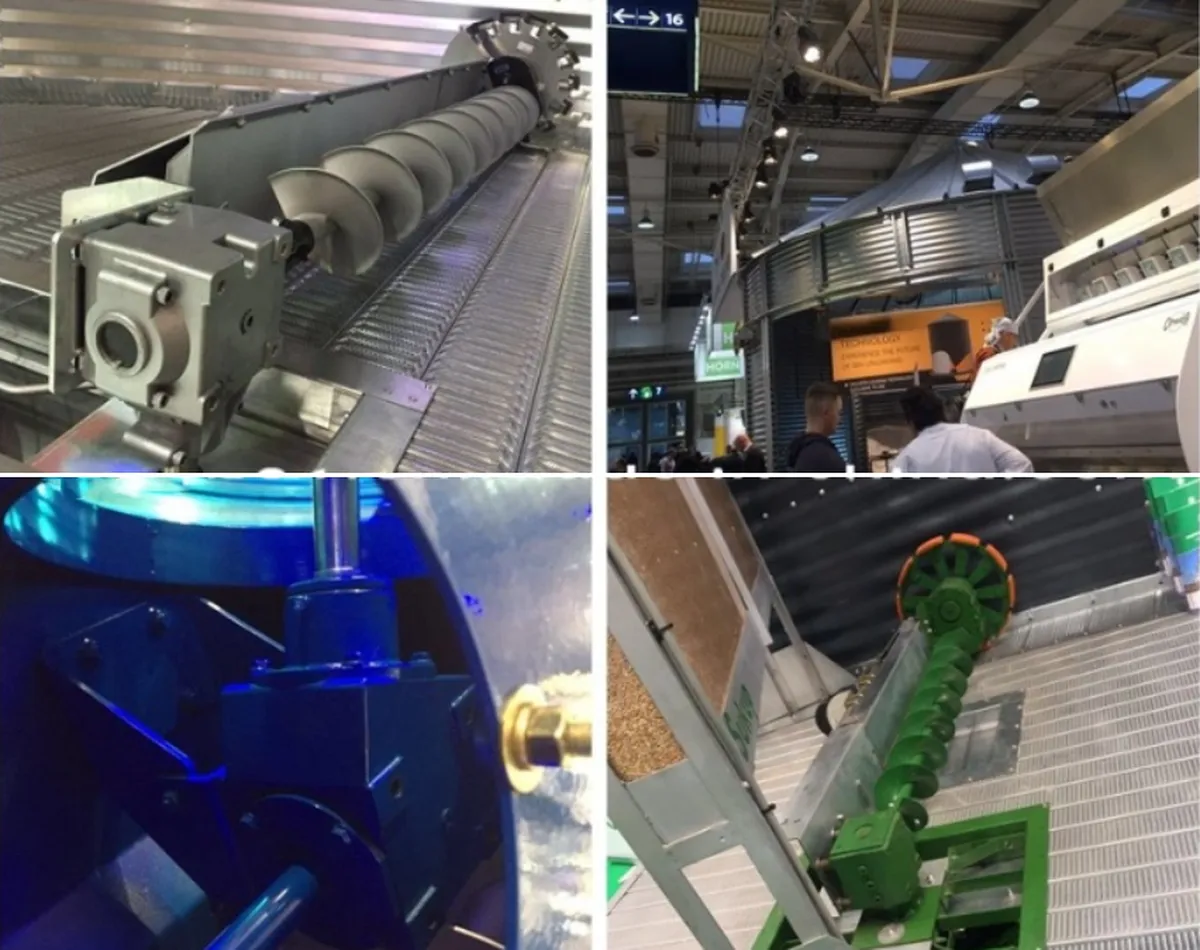

- Grain Handling Equipment: Repair services are essential for maintaining gearboxes in conveyors, augers, elevators, and other grain transportation machinery.

- Agricultural Machinery: Gearboxes used in tractors, combines, and other agricultural equipment require regular maintenance to ensure optimal performance.

- Processing Plants: Grain processing facilities rely on gearboxes to move, mix, and process grains efficiently.

- Storage Facilities: Gearboxes in grain storage and handling systems need to be well-maintained to prevent grain spoilage and contamination.

- Transportation Systems: Repair services are crucial for gearboxes used in grain transportation trucks, trailers, and railcars.

- Industrial Applications: Gearboxes used in industrial settings for material handling and processing require specialized repair services.

Key Components of Repair Services for Grain Auger Conveyor Gearbox

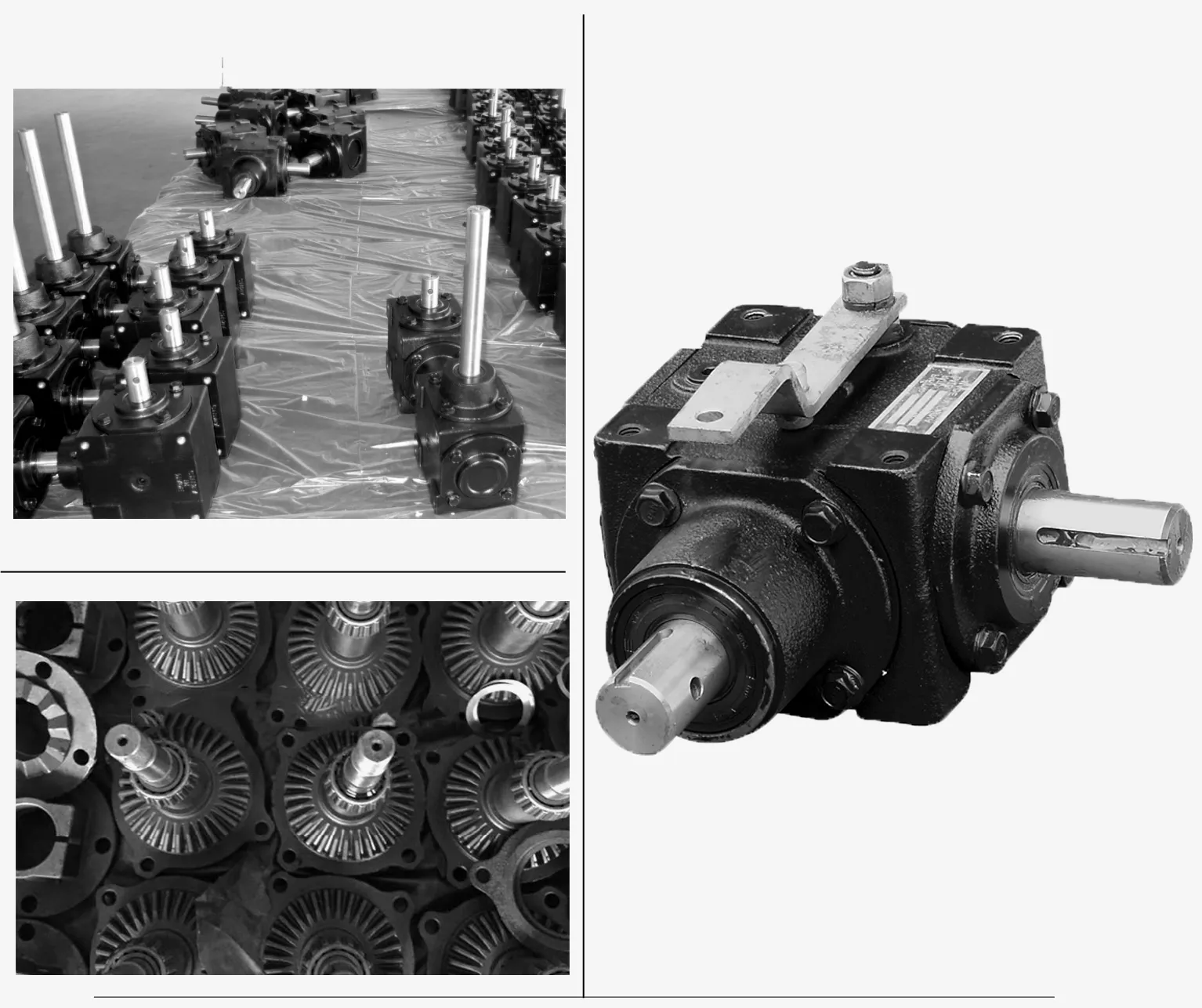

A grain transportation gearbox consists of several key components that work together to ensure efficient and reliable power transmission in agricultural machinery. Here are the main components:

- Gears: The heart of the gearbox, gears transfer power from the input shaft to the output shaft, altering the speed and torque.

- Bearings: Bearings support the rotating shafts and reduce friction between moving parts.

- Input and Output Shafts: The input shaft receives power from the motor or engine, while the output shaft delivers the modified power to the grain transportation machinery.

- Seals and Gaskets: These components prevent the leakage of lubricants and the ingress of contaminants.

- Housing/Casing: The gearbox housing encloses and protects all the internal components from external damage and contaminants.

- Lubrication System: Effective lubrication is critical for reducing friction and wear on gears and bearings.

Working Principle of Repair Services for Grain Auger Conveyor Gearbox

The working principle of a grain transportation gearbox involves the efficient transmission of mechanical power from a motor or engine to various grain-moving equipment. Here’s a detailed explanation:

- Power Input: The process begins with a motor or engine providing mechanical power.

- Gear Reduction: Inside the gearbox, the input shaft is connected to a set of gears.

- Torque Transmission: The gears inside the gearbox work in tandem to transmit the reduced speed and increased torque to the output shaft.

- Output Shaft: The output shaft, now rotating at a lower speed but with higher torque, is connected to the grain transportation machinery.

- Grain Movement: As the output shaft rotates, it drives the connected grain transportation equipment.

Selecting the Right Repair Services for Grain Auger Conveyor Gearbox

Selecting the right grain transportation gearbox for agricultural applications is critical for ensuring efficient and reliable operation. Here are some key points to consider:

- Load Capacity: Determine the maximum load capacity the gearbox needs to handle.

- Torque and Speed Requirements: Assess the torque and speed requirements of your grain transportation equipment.

- Gear Ratio: Select the appropriate gear ratio based on the desired speed reduction and torque increase.

- Durability and Material: Consider the materials used in the gearbox construction.

- Lubrication System: Evaluate the lubrication system of the gearbox.

- Compatibility and Integration: The selected gearbox must be compatible with the existing grain handling equipment.

Why Choose Hengchuang’s Repair Services for Grain Auger Conveyor Gearbox?

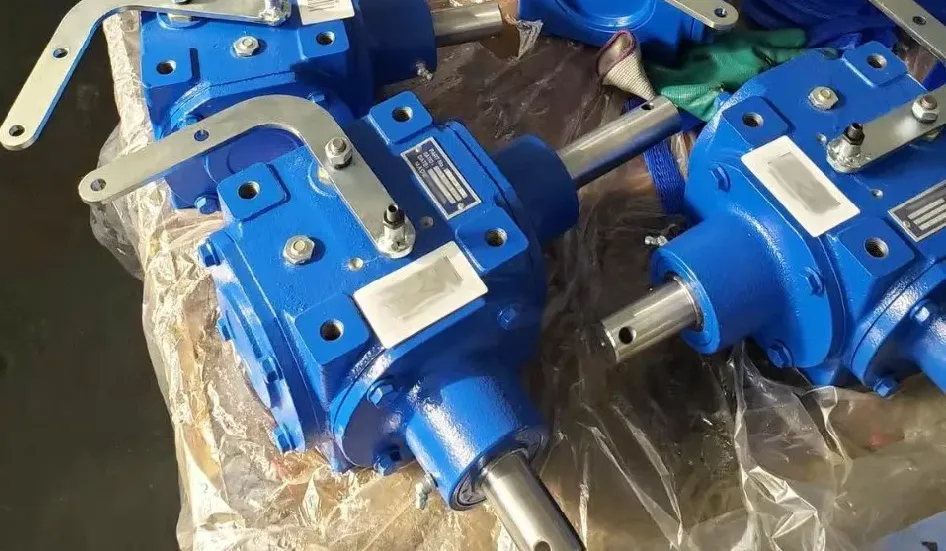

Hengchuang is a prominent manufacturer of high-performance grain transportation gearboxes for a variety of applications. Our repair services offer:

- Professionalism: Our technical staff are experts in gearbox design and repair.

- International Certifications: We adhere to international quality standards for our products and services.

- Customized Services: We can provide tailored solutions based on specific requirements.

- Production Facilities: Our state-of-the-art facilities ensure high-quality manufacturing.

- After-Sales Services: We offer comprehensive support and maintenance services for our gearboxes.

If you want to buy a grain transportation gearbox or avail of repair services, please get in touch with us.