Description

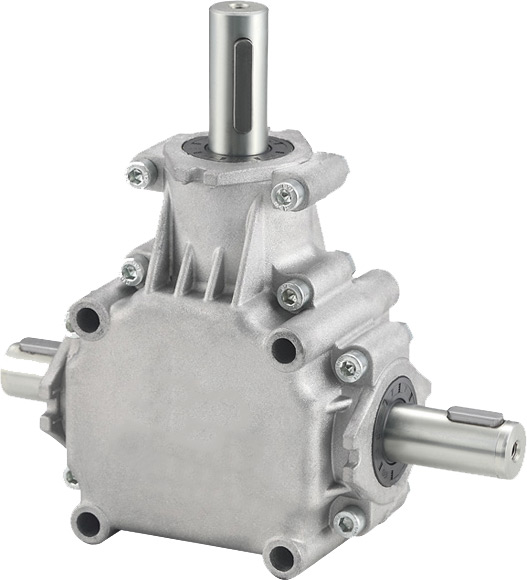

Durable Fertilizer Spreader Transmissions

Quality and Efficiency

We offer a diverse range of fertilizer spreader gearboxes, constructed from robust materials such as stainless steel and aluminum, ensuring extended service life and optimal performance. These corrosion-resistant materials, complemented by a specialized lubricant coating, enhance efficiency and durability. Our portfolio includes various sizes tailored to fit an array of systems, ensuring compatibility and performance optimization.

Variety and Customization in Wholesale

Our assortment of fertilizer spreader gearboxes is designed to cater to different spreader sizes and material types. Hand-crank gearboxes are ideal for smaller spreaders, while hydraulic or electric-powered variants suit larger units. Adaptability is further exhibited in optional fittings of augers or belt drives, and specialized gears that offer varied speeds, ensuring tailored solutions for specific operational needs.

Performance and Durability

Our gearboxes are engineered for diverse duty cycles, with options that offer extended run times and service life. Designed to operate efficiently for 8 to 12 hours, 5 days a week, our gearboxes also accommodate low-duty cycle applications, ensuring durability without compromising gear integrity. We’re committed to providing a gearbox solution aligned with your specific operational requirements.

Operational Mechanism

The fertilizer spreader gearbox, integral for efficient fertilizer distribution, is meticulously designed to ensure uniform application, minimizing waste and ecological footprint. Positioned near the spreader’s rear, it receives power from the tractor, driving the hopper’s spreading disc. The engineered blade design on the disc ensures consistent fertilizer dispersion across the field, eliminating clumping.

Material and Maintenance

Constructed from high-strength materials like cast iron or aluminum, our gearboxes withstand the demanding conditions of commercial use. Maintenance is paramount, with regular lubrication essential for smooth gear operation and prevention of premature wear. Keeping the gearbox clean and debris-free is equally vital to avert contamination and early failure.

Conclusion

In essence, our fertilizer spreader gearboxes are indispensable in contemporary agricultural machinery, aiding farmers in enhancing crop productivity and operational efficiency while mitigating environmental impact. Tailored to various operational scales and requirements, our gearboxes underscore the synergy of durability, efficiency, and adaptability.