PTO Driven Horizontal Feed Mixer Gearbox Sealing Techniques

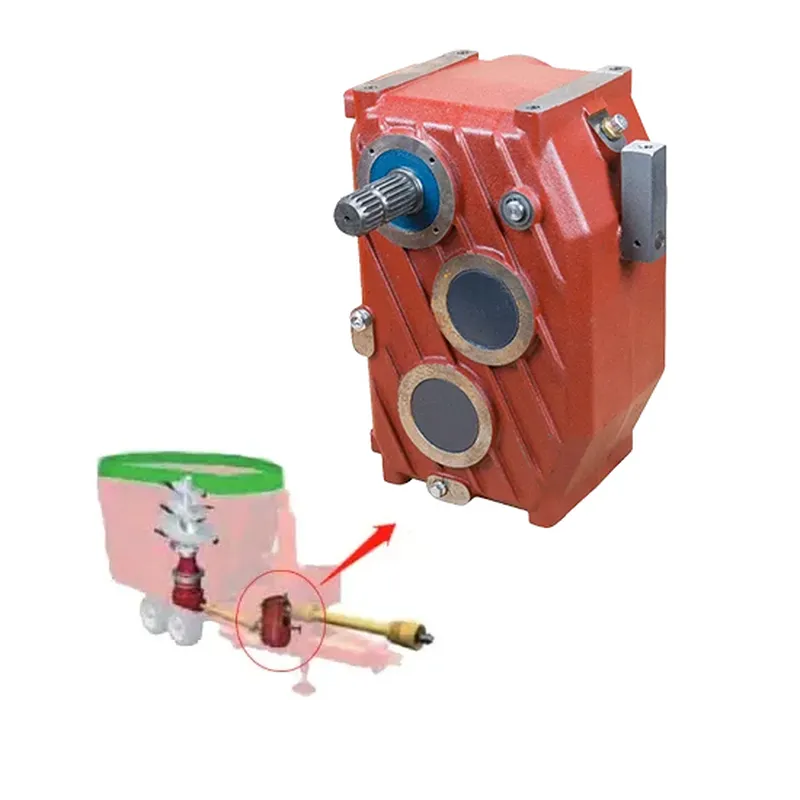

The PTO driven horizontal feed mixer gearbox is an essential component in the agricultural industry, used for efficiently mixing animal feed. This gearbox plays a crucial role in ensuring that the feed is thoroughly combined and ready for consumption by livestock. In this article, we will explore the various aspects of PTO driven horizontal feed mixer gearboxes, including their advantages, applications, working principle, proper lubrication, choosing the right PTO shaft, and why you should choose Hengchuang’s horizontal feed mixer gearbox.

Advantages of PTO Driven Horizontal Feed Mixer Gearbox

- High Mixing Efficiency: The gearbox enables efficient mixing of animal feed, ensuring uniform distribution of nutrients.

- Durable Construction: PTO driven horizontal feed mixer gearboxes are built to withstand heavy loads and harsh operating conditions.

- Cost-Effective Solution: Investing in a high-quality gearbox reduces maintenance costs and increases productivity.

- Easy Maintenance: With proper care and lubrication, these gearboxes require minimal maintenance for long-term use.

- Customizable Options: Gearboxes can be tailored to specific requirements, providing flexibility in feed mixing operations.

- Improved Feed Quality: The thorough mixing process results in high-quality feed that promotes animal health and growth.

Applications of PTO Driven Horizontal Feed Mixer Gearbox

- Cattle Farms: Used for mixing feed for cattle to ensure proper nutrition and growth.

- Poultry Farms: Essential for blending feed ingredients for poultry to meet dietary requirements.

- Swine Operations: Enables the efficient mixing of feed for swine to optimize growth and health.

- Feed Milling Facilities: Industrial-scale feed mixing operations benefit from the precision and efficiency of these gearboxes.

- Animal Husbandry: Small and large-scale animal husbandry operations rely on these gearboxes for feed preparation.

- Agricultural Cooperatives: Collaborative efforts in agriculture utilize these gearboxes for feed processing and distribution.

Working Principle of PTO Driven Horizontal Feed Mixer Gearbox

The working principle of a tractor PTO driven horizontal feed mixer gearbox involves a series of mechanical processes that facilitate the efficient mixing of animal feed.

- PTO Engagement: The process begins when the tractor’s PTO is activated.

- Power Transmission: Once engaged, the rotary motion of the tractor’s engine is transmitted to the gearbox.

- Speed Reduction: Gears within the gearbox reduce the speed of rotation while increasing torque.

- Torque Amplification: The gearbox amplifies torque for mixing dense feed materials.

- Power Output: Transformed power is transmitted to the mixing mechanism of the feed mixer.

- Operational Control: The gearbox provides flexibility through selectable gear ratios or variable speed setups.

Proper Lubrication of PTO Driven Horizontal Feed Mixer Gearbox

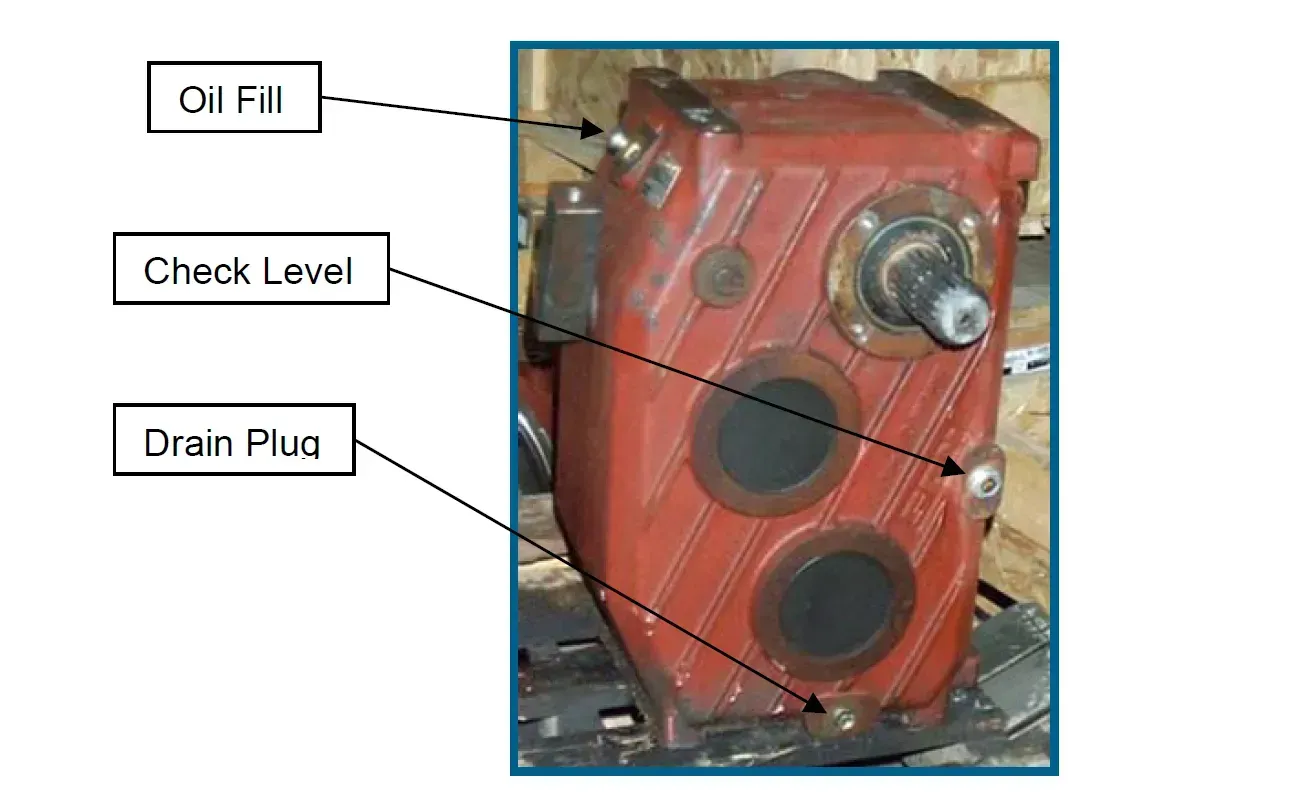

- Choosing the Right Lubricant: Select a high-quality gear oil that matches gearbox specifications.

- Regular Lubricant Checks: Monitor and maintain lubricant levels and quality to prevent wear and failure.

- Changing the Lubricant: Follow recommended intervals for lubricant changes to ensure effectiveness.

- Lubrication Points Maintenance: Keep all lubrication points clean and properly greased for optimal performance.

- Monitoring for Leaks: Inspect the gearbox for oil leaks and replace worn seals promptly.

- Temperature Monitoring: Keep track of operating temperatures to prevent overheating and lubricant breakdown.

Choose the Right PTO Shaft for Horizontal Feed Mixer Gearbox

- Determine the Required Length: Measure the distance between the tractor’s PTO output and the gearbox input.

- Check the Power Requirements: Ensure the PTO shaft can handle the maximum power output without overloading.

- Choose the Right Spline Specification: Match spline sizes to avoid connection issues and ensure efficient power transmission.

- Shaft the Safety Features: Look for safety features to protect operators from injuries.

- PTO Shaft Quality and Durability: Select a durable shaft made from high-quality materials for longevity.

- Compatibility with Tractor and Gearbox: Verify that the PTO shaft works seamlessly with all machinery components.

Why Choose Hengchuang’s Horizontal Feed Mixer Gearbox?

Hengchuang is a leading manufacturer of high-performance horizontal feed mixer gearboxes, offering a range of options for various applications. Our gearboxes are designed for durability, efficiency, and precision mixing of animal feed. With a team of experienced technical staff, we can customize gearboxes to meet specific requirements and ensure optimal performance.

Professionalism

Our company prides itself on professionalism in all aspects of production and service delivery. We prioritize quality, reliability, and customer satisfaction in everything we do.

International Certifications

Hengchuang holds international certifications that attest to our commitment to quality standards and compliance with industry regulations. Our gearboxes meet the highest international benchmarks for performance and safety.

Customized Services

We offer customized services to tailor gearboxes to unique specifications and requirements. Our technical expertise allows us to design and manufacture gearboxes that meet the specific needs of our customers.

Production Facilities

Our state-of-the-art production facilities are equipped with advanced machinery and technology to ensure efficient and precise manufacturing processes. We maintain high standards of quality control and efficiency in our production operations.

After-Sales Services

At Hengchuang, we provide comprehensive after-sales services to support our customers and ensure the continued performance of our gearboxes. Our team is committed to assisting with maintenance, repairs, and technical support whenever needed.

Conclusion

By choosing Hengchuang’s horizontal feed mixer gearbox, you can benefit from a reliable, efficient, and durable solution for your feed mixing needs. Our commitment to quality, customization, and customer satisfaction sets us apart as a leading manufacturer in the industry.

Author: Yjx