Introduction to Noise Reduction Strategies for Square Baler Gearbox

Noise reduction strategies for square baler gearboxes are crucial for maintaining a quiet and efficient operation. These strategies involve various techniques and components designed to minimize noise levels during the baling process.

Advantages of Noise Reduction Strategies for Square Baler Gearbox

Implementing noise reduction strategies for square baler gearboxes offers several advantages:

- Improved Operator Comfort: Reduced noise levels create a more comfortable working environment for operators, leading to increased productivity.

- Enhanced Equipment Longevity: Lower noise levels can help extend the lifespan of the gearbox and other components by reducing wear and tear.

- Compliance with Regulations: Noise reduction strategies can help ensure compliance with noise regulations in agricultural settings.

- Reduced Environmental Impact: Quieter operation minimizes noise pollution in the surrounding area, benefiting both workers and the environment.

- Enhanced Safety: Lower noise levels can improve safety by allowing operators to hear potential hazards more clearly during operation.

- Optimized Performance: Noise reduction strategies can contribute to smoother operation and improved overall performance of the square baler gearbox.

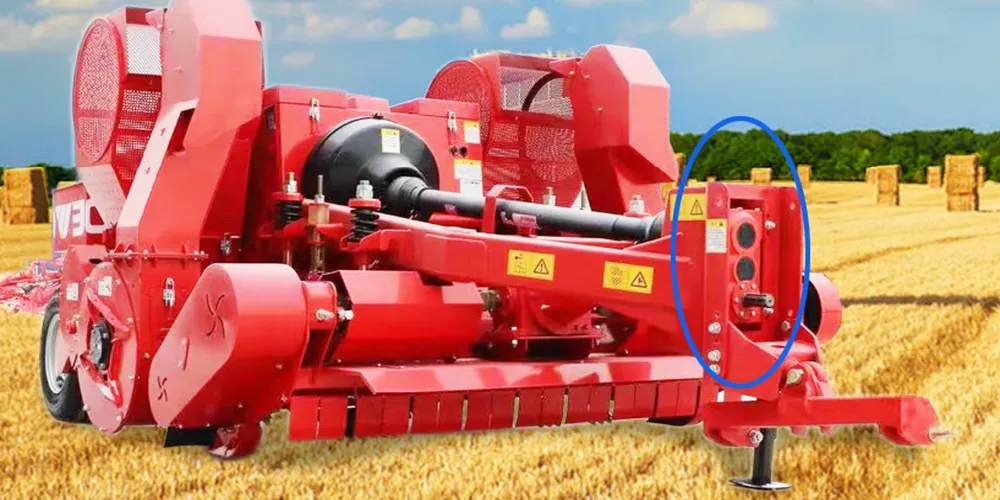

Applications of Noise Reduction Strategies for Square Baler Gearbox

Noise reduction strategies for square baler gearboxes can be applied in various settings and scenarios:

- Commercial Farming Operations

- Industrial Agriculture Machinery

- Livestock Feed Production Facilities

- Hay and Silage Processing Plants

- Agricultural Equipment Manufacturing

- Rural Agricultural Communities

Working Principle of Noise Reduction Strategies for Square Baler Gearbox

The working principle of noise reduction strategies for a square baler gearbox involves several key steps:

- Soundproofing Materials: Adding soundproofing materials to the gearbox housing can help absorb and dampen noise generated during operation.

- Vibration Dampening: Installing vibration dampeners on critical components can reduce noise caused by mechanical vibrations.

- Precision Engineering: Designing gearbox components with tight tolerances and high-quality materials can contribute to quieter operation.

- Optimized Gear Design: Implementing precision-cut gears and optimized gear ratios can minimize noise levels during gear meshing.

- Maintenance Practices: Regular maintenance and lubrication of gearbox components can prevent excessive noise due to wear and friction.

- Advanced Technology: Utilizing advanced noise reduction technologies, such as acoustic enclosures or insulation, can further reduce noise levels.

Installation Steps for Noise Reduction Strategies for Square Baler Gearbox

Proper installation of noise reduction strategies for a square baler gearbox is essential for optimal performance:

- Preparation and Safety Measures

- Aligning the Gearbox with the Baler

- Securing the Gearbox to the Baler

- Connecting the PTO Shaft

- Lubrication and Fluid Levels

- Testing and Adjustment

Proper Maintenance of Noise Reduction Strategies for Square Baler Gearbox

Maintaining noise reduction strategies for a square baler gearbox is essential for long-term performance:

- Regular Inspection

- Lubrication

- Cleaning

- Checking for Leaks

- Tightening Bolts and Fasteners

- Monitoring Gearbox Temperature

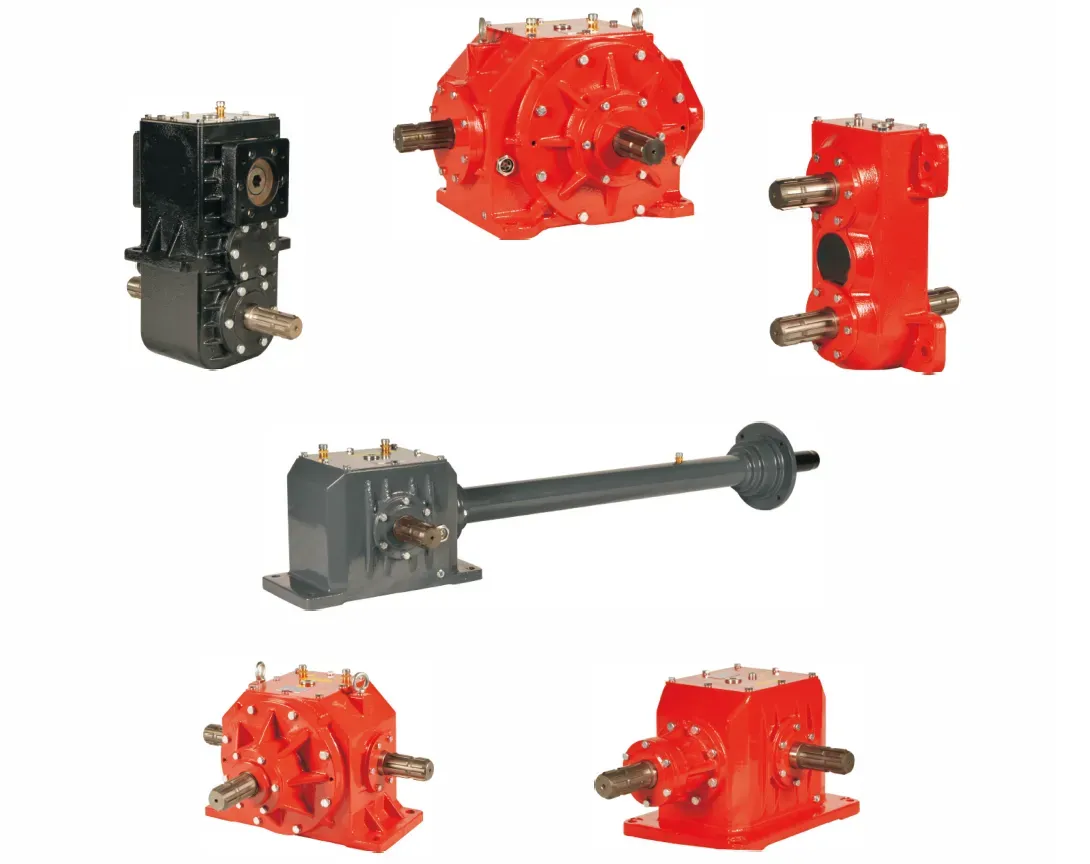

Why Choose Hengchuang’s Square Baler Gearboxes?

Hengchuang offers high-quality square baler gearboxes with advanced noise reduction strategies:

- Professionalism: Hengchuang’s team of experts provides professional guidance and support for all gearbox needs.

- International Certifications: Our gearboxes meet international quality standards and certifications for reliable performance.

- Customized Services: We offer custom gearbox designs to meet specific application requirements.

- Production Facilities: Hengchuang’s state-of-the-art production facilities ensure precision manufacturing and quality control.

- After-Sales Services: Our dedicated after-sales team provides maintenance support and technical assistance.

- Wide Range of Products: In addition to square baler gearboxes, we offer various agricultural gearboxes and PTO shafts for diverse applications.

For more information on noise reduction strategies for square baler gearboxes and to explore our product offerings, contact Hengchuang today.

About the Author

Author: Yjx