Horizontal Feed Mixer Gearbox Input Shaft Specifications

The Horizontal Feed Mixer Gearbox Input Shaft is a crucial component in the operation of feed mixers used in agricultural settings. This article will provide a detailed overview of the specifications, advantages, applications, working principle, proper lubrication, and selection of the right PTO shaft for a horizontal feed mixer gearbox. Additionally, we will explore why choosing Hengchuang’s Horizontal Feed Mixer Gearbox is a wise decision for your agricultural machinery needs.

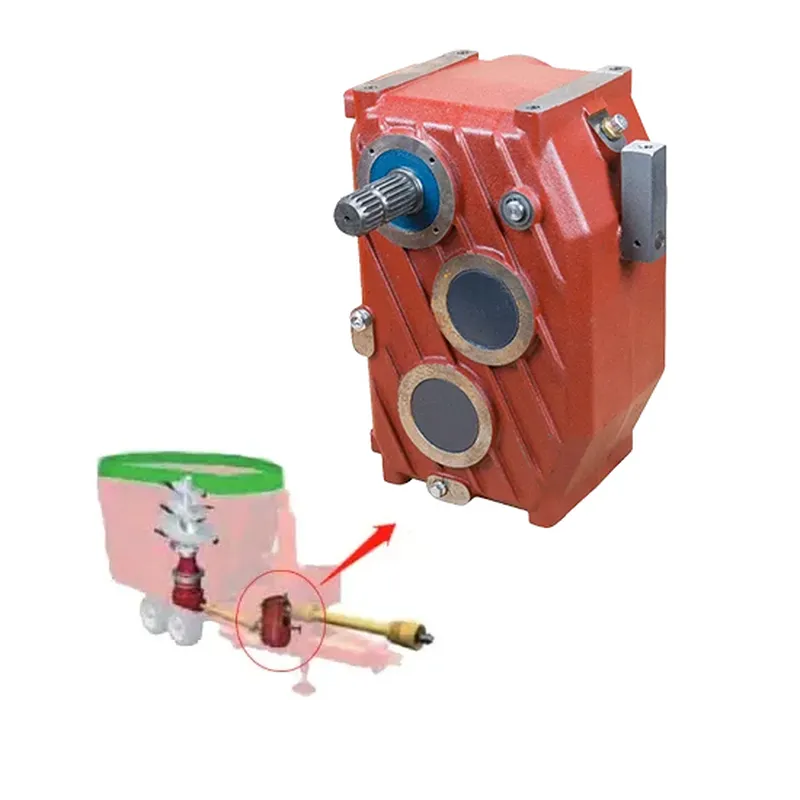

What is a Horizontal Feed Mixer Gearbox?

A Horizontal Feed Mixer Gearbox is a mechanical device that is used to mix animal feed efficiently. It is typically driven by a tractor’s power take-off (PTO) system and consists of various gears that work together to reduce the rotational speed of the input shaft while increasing torque. This allows for thorough mixing of feed materials, ensuring uniformity and consistency in the final product.

Advantages of Horizontal Feed Mixer Gearbox

- Efficient mixing of animal feed

- Uniformity and consistency in feed composition

- Increased productivity and reduced manual labor

- Durable construction for long-term use

- Compatibility with various tractor models

- Customizable features for specific applications

Applications of Horizontal Feed Mixer Gearbox

- Animal farms

- Feed processing plants

- Agricultural cooperatives

- Ranches and livestock operations

- Dairy farms

- Poultry farms

Working Principle of Horizontal Feed Mixer Gearbox

The working principle of a tractor PTO driven horizontal feed mixer gearbox involves a series of mechanical processes that facilitate the efficient mixing of animal feed. Here’s a detailed explanation of how it works:

- PTO Engagement: The process begins when the tractor’s PTO is activated.

- Power Transmission: Once engaged, the rotary motion of the tractor’s engine is directly transmitted to the gearbox via the PTO shaft.

- Speed Reduction: Within the gearbox, this high-speed rotational power is passed through a series of gears.

- Torque Amplification: As the gearbox reduces the input speed, it increases the torque.

- Power Output: The transformed power with lower speed and higher torque is then transmitted through the gearbox’s output shaft to the mixing mechanism of the feed mixer.

- Operational Control and Flexibility: The gearbox provides flexibility in operation through selectable gear ratios or a variable speed setup.

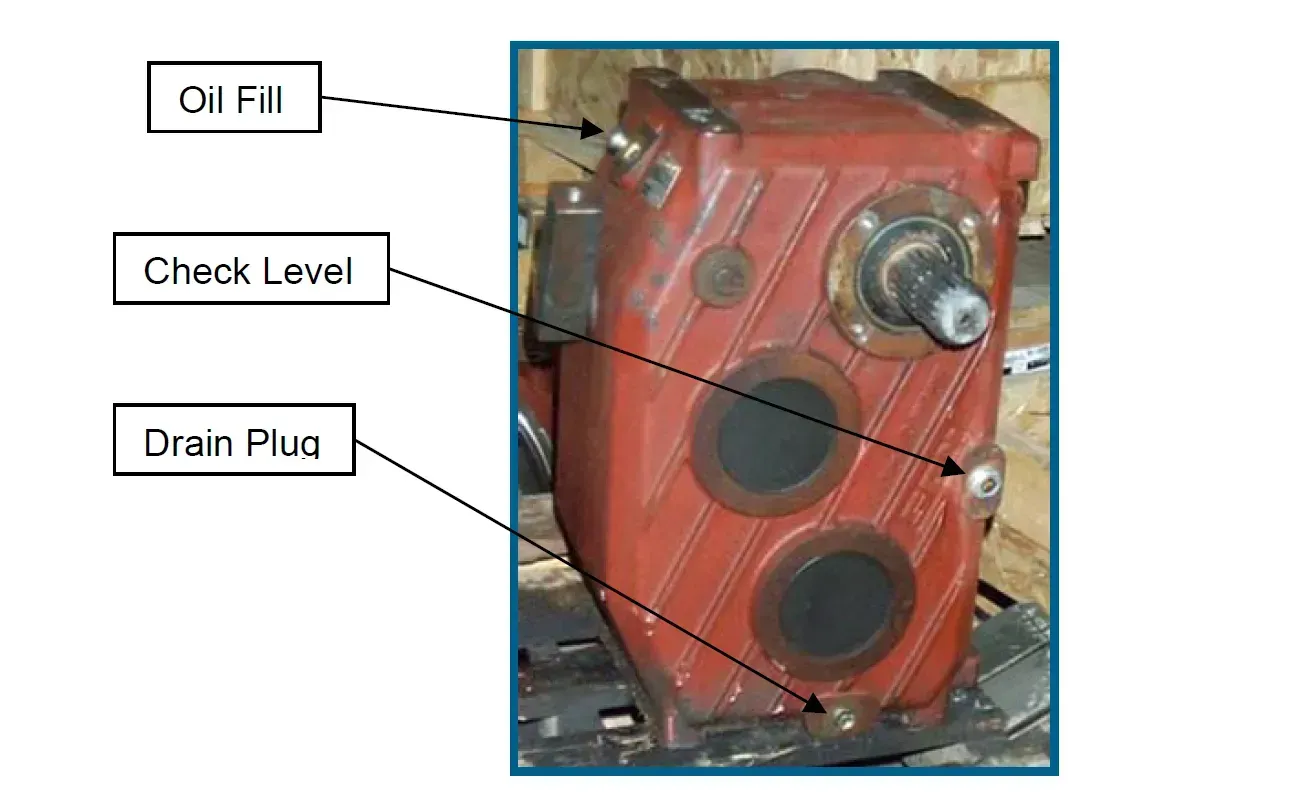

Proper Lubrication of Horizontal Feed Mixer Gearbox

Proper lubrication is crucial for the efficient and durable operation of a tractor PTO driven horizontal feed mixer gearbox. By adhering to these lubrication practices, you can ensure smooth and reliable operation.

- Choosing the Right Lubricant

- Regular Lubricant Checks

- Changing the Lubricant

- Lubrication Points Maintenance

- Monitoring for Leaks

- Temperature Monitoring

Choose the Right PTO Shaft for Horizontal Feed Mixer Gearbox

Choosing the right PTO shaft for a horizontal feed mixer gearbox is critical for ensuring efficient operation and preventing mechanical failures. By carefully considering these factors, you can select a PTO shaft that meets your operational needs.

- Determine the Required Length

- Check the Power Requirements

- Choose the Right Spline Specification

- Shaft the Safety Features

- PTO Shaft Quality and Durability

- Compatibility with Tractor and Mixer Gearbox

Why Choose Hengchuang’s Horizontal Feed Mixer Gearbox?

Hengchuang is a leading manufacturer of high-performance horizontal feed mixer gearboxes for various applications. Our gearboxes are designed to meet the needs of agricultural operations, offering efficiency, durability, and reliability.

Professionalism

Hengchuang prides itself on professionalism in every aspect of our operations, from product design to customer service.

International Certifications

Our gearboxes meet international quality standards and are certified for performance and safety.

Customized Services

We offer customized gearbox solutions to meet the specific requirements of our customers.

Production Facilities

Our state-of-the-art production facilities ensure the highest quality standards are met in every gearbox we manufacture.

After-Sales Services

Hengchuang provides excellent after-sales support to assist customers with any technical issues or maintenance needs.