Exploring the Horizontal Feed Mixer Gearbox Bearing Types

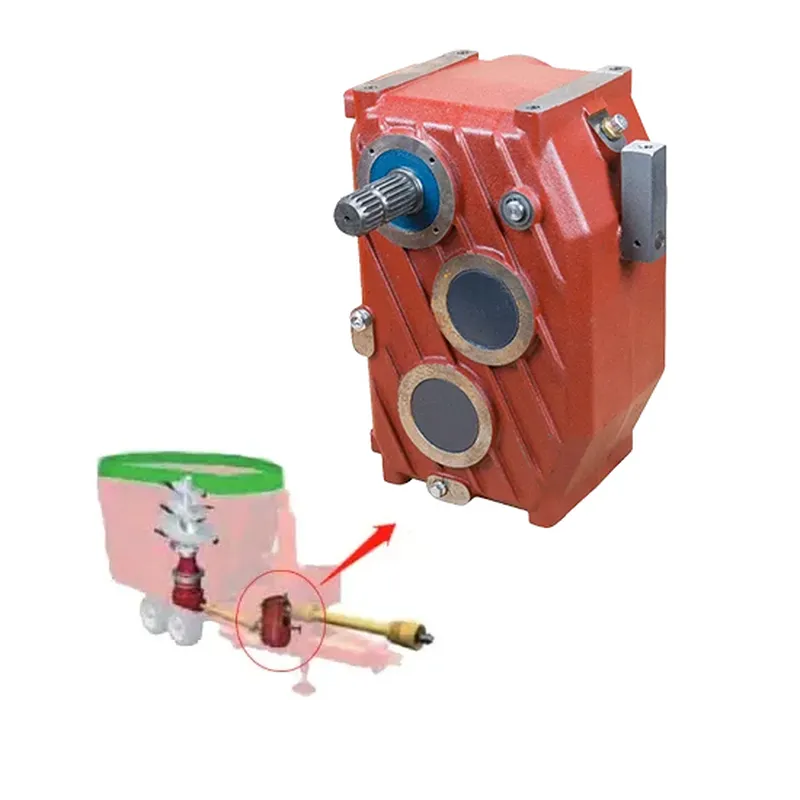

In the realm of agricultural machinery, the horizontal feed mixer gearbox plays a crucial role in efficiently mixing animal feed to meet the nutritional needs of livestock. This essential component relies on various types of bearings to ensure smooth operation and longevity. Let’s delve into the world of horizontal feed mixer gearbox bearing types to understand their significance in this vital agricultural equipment.

Advantages of Horizontal Feed Mixer Gearbox

Horizontal feed mixer gearboxes offer a multitude of advantages that make them indispensable in modern farming operations:

- Efficient Mixing: Horizontal feed mixer gearboxes facilitate the thorough blending of various feed ingredients, ensuring uniform distribution of nutrients.

- Durable Construction: These gearboxes are built to withstand the rigors of daily use in agricultural settings, offering long-lasting performance.

- Customizable Options: Manufacturers like Hengchuang provide customizable gearbox solutions to meet specific application requirements.

- High Torque Transmission: Horizontal feed mixer gearboxes are designed to handle high torque loads, making them ideal for mixing dense feed materials.

- Operational Flexibility: With adjustable gear ratios and variable speed setups, operators can fine-tune the mixing process for optimal results.

- Reliable Performance: Horizontal feed mixer gearboxes ensure consistent and reliable performance, minimizing downtime on the farm.

Applications of Horizontal Feed Mixer Gearbox

The versatility of horizontal feed mixer gearboxes extends to various agricultural applications:

- Poultry Farming: Horizontal feed mixer gearboxes are used to blend poultry feed with precise ingredient ratios for optimal growth and health.

- Cattle Ranching: These gearboxes play a crucial role in mixing nutritious feed for cattle to support their overall well-being and productivity.

- Swine Production: Horizontal feed mixer gearboxes are essential for creating balanced pig feed formulations that promote healthy growth and development.

- Sheep and Goat Farming: Farmers rely on horizontal feed mixer gearboxes to create specialized feed mixes tailored to the nutritional needs of sheep and goats.

- Horse Breeding: In the equine industry, these gearboxes are used to blend high-quality feed to support the performance and health of horses.

- Wildlife Conservation: Horizontal feed mixer gearboxes are utilized in wildlife sanctuaries and conservation efforts to prepare specialized diets for exotic animals.

Working Principle of Horizontal Feed Mixer Gearbox

The working principle of a tractor PTO driven horizontal feed mixer gearbox involves a series of mechanical processes that facilitate efficient mixing of animal feed:

- PTO Engagement: The process begins when the tractor’s PTO is activated, transferring mechanical power to the gearbox.

- Power Transmission: The rotary motion from the tractor’s engine is transmitted to the gearbox at a reduced speed but increased torque.

- Speed Reduction: Gears within the gearbox reduce the rotational speed while amplifying torque for effective mixing.

- Torque Amplification: The gearbox enhances torque to handle dense feed materials without straining the tractor’s engine.

- Power Output: Transformed power is transmitted to the mixing mechanism for thorough blending of feed ingredients.

- Operational Control: The gearbox offers flexibility through selectable gear ratios, allowing operators to adjust mixing speed as needed.

Proper Lubrication of Horizontal Feed Mixer Gearbox

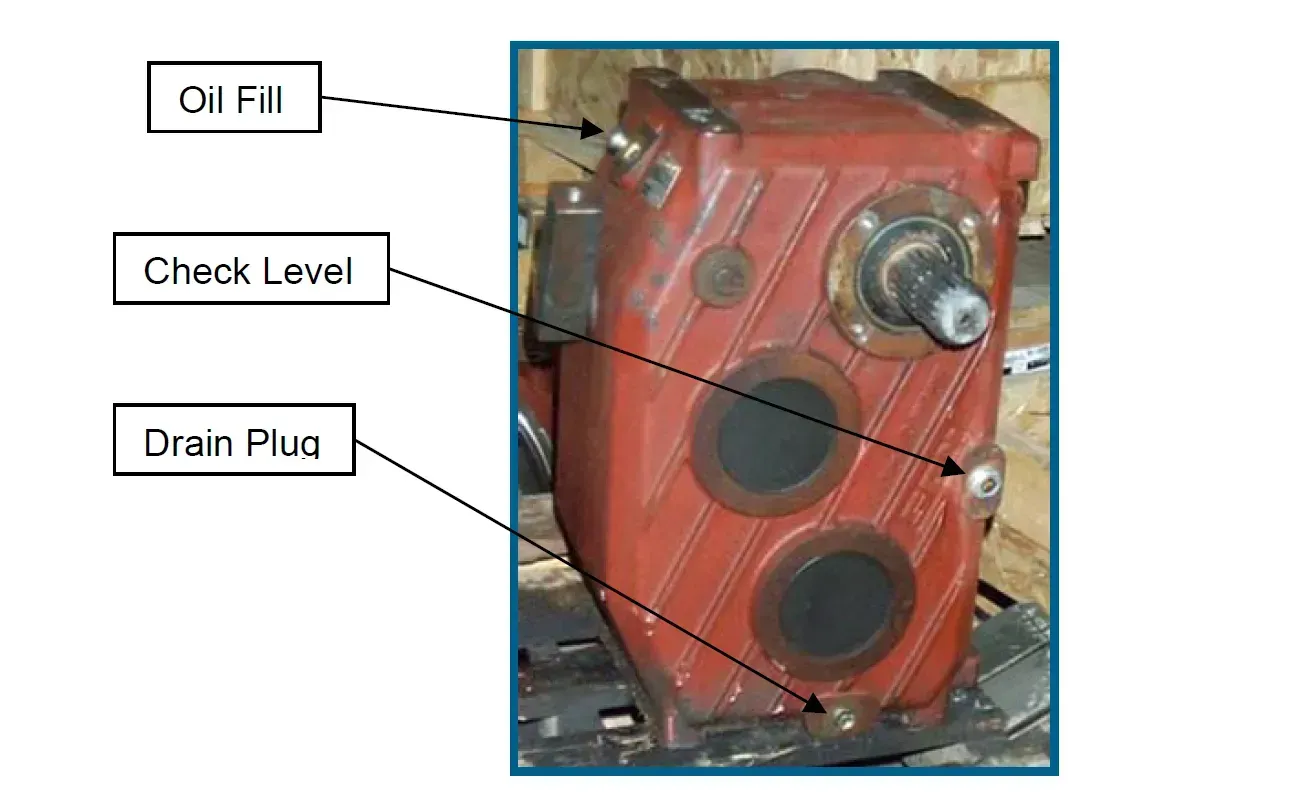

Proper lubrication is essential for the efficient operation and longevity of a horizontal feed mixer gearbox:

- Choosing the Right Lubricant: Select a high-quality gear oil that matches the gearbox specifications for optimal performance.

- Regular Lubricant Checks: Monitor lubricant levels and quality to prevent wear and potential failures.

- Changing the Lubricant: Replace the lubricant at recommended intervals to maintain gearbox efficiency.

- Lubrication Points Maintenance: Ensure all lubrication points are clean and accessible for proper lubricant application.

- Monitoring for Leaks: Inspect the gearbox for oil leaks and replace worn seals to prevent lubricant loss.

- Temperature Monitoring: Keep an eye on gearbox temperature to prevent overheating and ensure proper lubricant performance.

Choose the Right PTO Shaft for Horizontal Feed Mixer Gearbox

Choosing the appropriate PTO shaft is crucial for optimal performance and safety:

- Determine the Required Length: Select a shaft that fits the distance between the tractor’s PTO output and the gearbox input.

- Check the Power Requirements: Ensure the PTO shaft can handle the maximum power output without overloading.

- Choose the Right Spline Specification: Match the spline count and size to avoid connection issues and ensure efficient power transmission.

- Shaft Safety Features: Look for a shaft with safety features like shields to protect operators from injuries.

- PTO Shaft Quality: Select a high-quality shaft made from durable materials for long-lasting performance.

- Compatibility: Verify that the PTO shaft is fully compatible with the tractor and gearbox to prevent operational issues.

Why Choose Hengchuang’s Horizontal Feed Mixer Gearbox?

Hengchuang is a leading manufacturer of high-performance horizontal feed mixer gearboxes, offering a wide range of benefits:

- Professionalism: Hengchuang’s team of experts ensures top-notch quality and service for all gearbox solutions.

- International Certifications: Our gearboxes meet international standards for quality and performance, guaranteeing reliability.

- Customized Services: We provide tailored gearbox solutions to meet specific application needs for optimal efficiency.

- Production Facilities: Our state-of-the-art manufacturing facilities ensure precision and quality in every gearbox produced.

- After-Sales Services: Hengchuang offers comprehensive after-sales support to address any queries or concerns post-purchase.

- Global Reach: With a worldwide presence, Hengchuang serves customers across the globe with top-tier gearbox solutions.

Author: Yjx