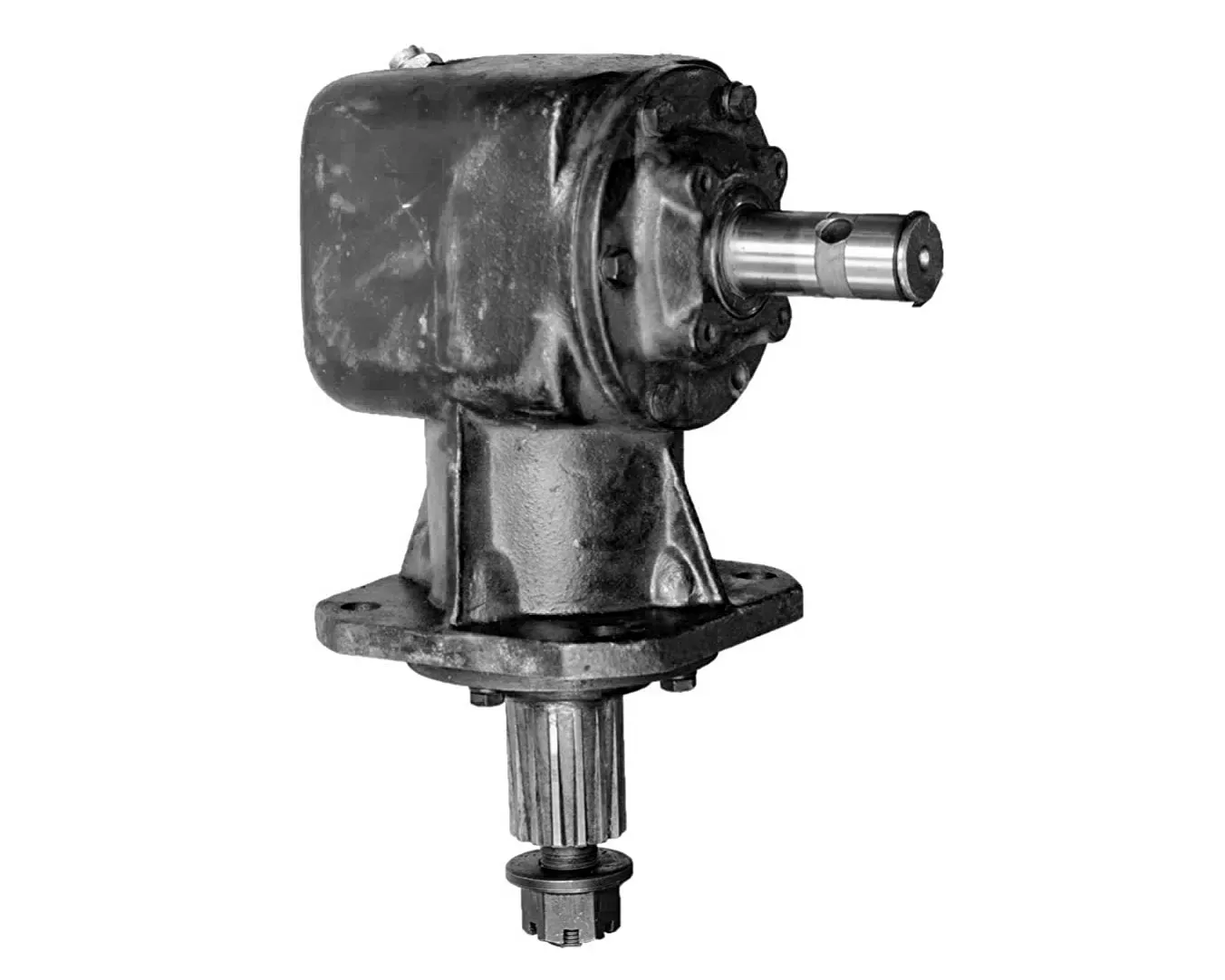

Common Troubleshooting Issues in RC-81 Rotary Cutter Gearbox

The RC-81 Rotary Cutter Gearbox is a crucial component in agricultural machinery, responsible for converting power from the tractor into precise cutting action. This gearbox is designed to handle the demands of cutting grass and vegetation efficiently, making it a valuable tool for maintaining green areas. In this article, we will explore the common troubleshooting issues that may arise with the RC-81 Rotary Cutter Gearbox and how to address them effectively.

Excessive Noise or Vibration

If you notice that the RC-81 Rotary Cutter Gearbox is making unusual noises or vibrating excessively during operation, it could indicate worn or damaged gears and bearings. To address this issue, check for loose components, ensure all fasteners are tightened properly, and inspect the gears and bearings for signs of wear. Replacing worn parts and securing all connections can often resolve these noise and vibration problems.

Gearbox Overheating

An RC-81 Rotary Cutter Gearbox that is running hotter than usual may be experiencing insufficient lubrication or an overload condition. Begin by checking the oil level and the quality of the lubricant in the gearbox. If the oil is low or contaminated, it should be replaced. Additionally, make sure that the workload on the gearbox is within the manufacturer’s specified operational limits to prevent overheating.

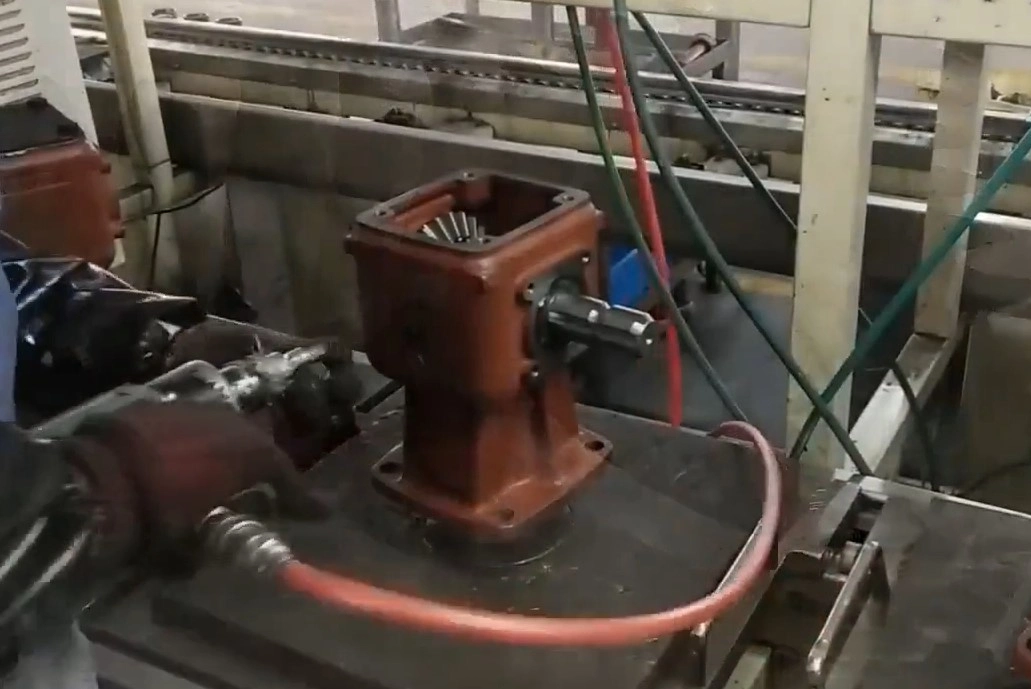

Leaking Oil from the Gearbox

Oil leaks in the RC-81 Rotary Cutter Gearbox can result from damaged seals, loose connections, or cracks in the gearbox casing. Inspect the seals around the input and output shafts for wear and replace them if necessary. Tighten all bolts and connections securely, and if the casing is cracked, consider welding or replacing it to prevent oil leaks.

Gearbox Difficulty Engaging or Disengaging

If the RC-81 Rotary Cutter Gearbox does not engage or disengage smoothly, the linkage between the PTO and the gearbox may require adjustment or lubrication. Check the PTO shaft and associated linkage for any obstructions, misalignment, or dry joints. Lubricating the moving parts and adjusting the linkage as needed can help resolve issues with engaging or disengaging the gearbox.

Decreased Cutting Performance

When the rotary cutter does not perform as expected, the issue may be related to the gearbox not transmitting enough torque to the blades. Verify that the gearbox’s output torque is suitable for the cutting task at hand. Check for worn or dull blades, improper gear settings, or a mismatch between the gearbox and the tractor’s power output to address any issues affecting cutting performance.

Power Transmission Issues

If there is a lack of power transmission from the tractor to the RC-81 Rotary Cutter Gearbox, inspect the PTO shaft and couplings for damage or wear. Ensure that the drive shaft is securely connected and free of significant wear. Look for any obstructions that may be impeding the movement or connection of the shaft to resolve power transmission issues effectively.